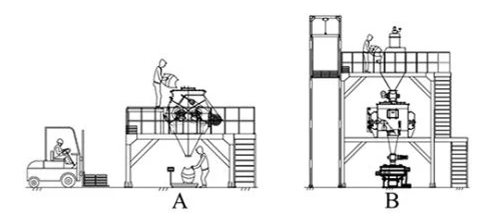

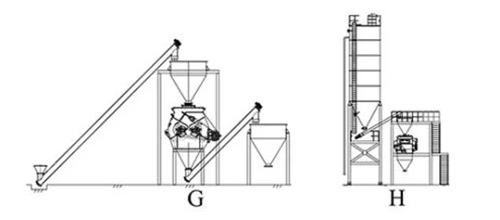

Introducing our state-of-the-art drying and mixing machines designed to revolutionize the way you process and prepare your products. This innovative machine is the perfect solution for businesses looking to streamline their production processes and achieve consistent, high-quality results.

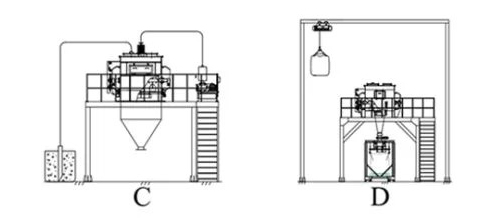

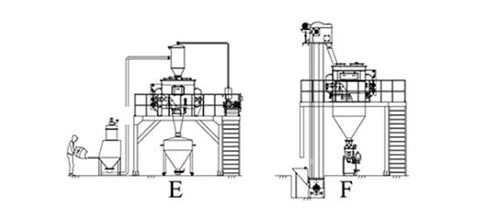

Our drying and mixing machines are equipped with advanced technology to ensure efficient and precise drying and mixing of various materials. Whether you're dealing with powders, granules or other materials, our machines can handle it with ease. The machine's powerful drying capabilities ensure fast and efficient moisture removal, resulting in a high-quality end product.

One of the key features of our machines is the ability to mix materials to a precise and uniform consistency. This is achieved through a carefully designed mixing mechanism that ensures thorough mixing without compromising the integrity of the material. The result is a perfectly blended product that meets the highest standards of quality and consistency.

In addition to superior performance, our dryers and mixers are designed with user convenience in mind. Intuitive controls and a user-friendly interface make it easy to operate and can be seamlessly integrated into your production process. The machine has also been designed with durability and reliability in mind, ensuring it can withstand the demands of continuous use in a production environment.

Additionally, our machines are designed with safety at the forefront. It is equipped with advanced safety features to protect the operator and the product being processed, giving you peace of mind while the machine is running.

Whether you are in food, pharmaceutical, chemical or any other industry that requires precise drying and mixing, our machines are the perfect solution for your needs. With their cutting-edge technology, user-friendly design and exceptional performance, our dryers and mixers are ideal for businesses looking to take their production processes to the next level. Experience the difference our machines can make for your business and take your production capabilities to the next level.

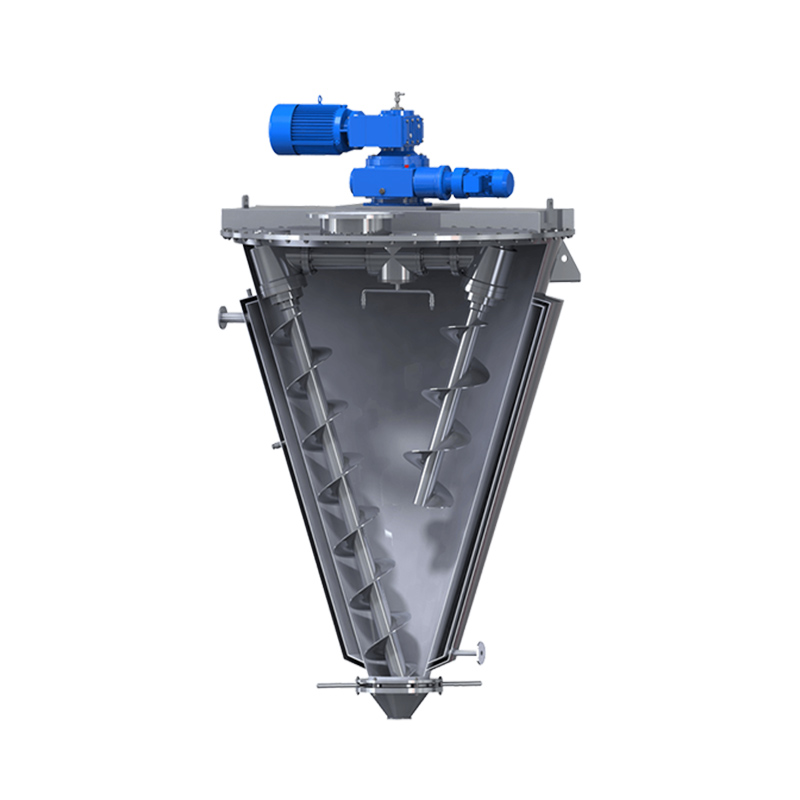

Conical Screw Mixer

Conical Screw Mixer Conical Screw Belt Mixer

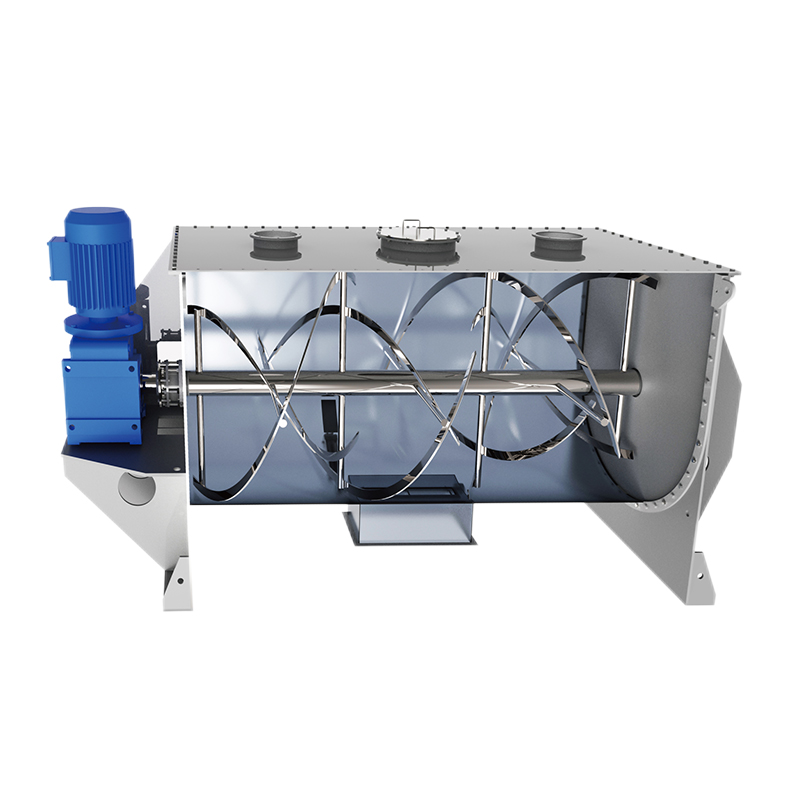

Conical Screw Belt Mixer Ribbon Blender

Ribbon Blender Plough-shear Mixer

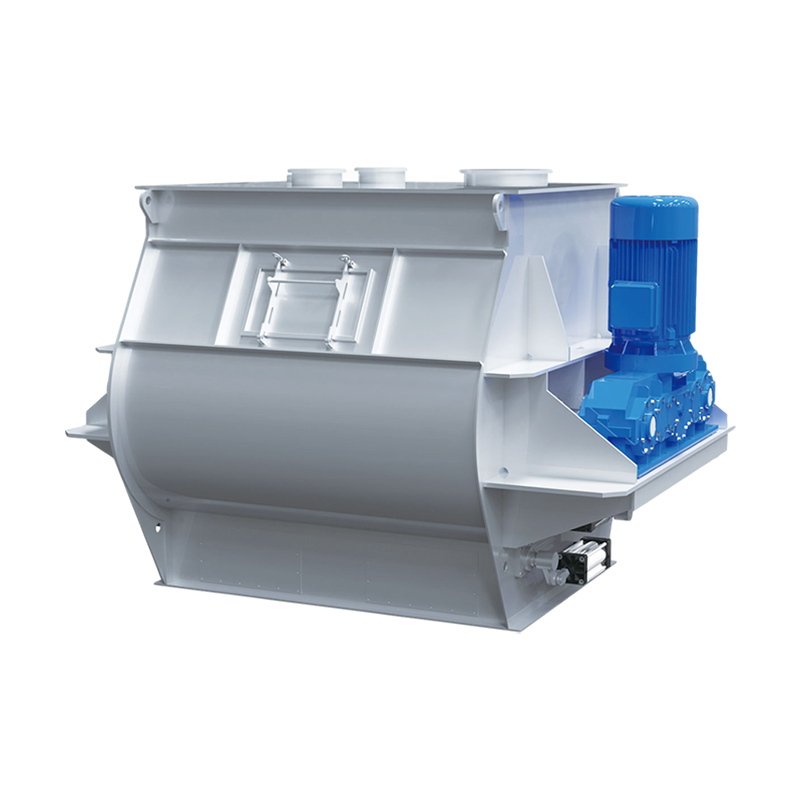

Plough-shear Mixer Double Shaft Paddle Mixer

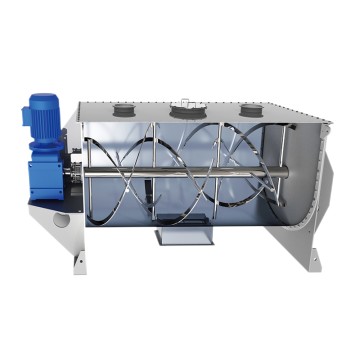

Double Shaft Paddle Mixer CM Series Mixer

CM Series Mixer