The HC-VSH Series of Special Conical Double-Spiral Machines for Photovoltaic Plastic Films

Description

Equipment Specifications

Product Parameters

|

Model |

Allowable working volume |

Spindle speed(RPM) |

Motor power(KW) |

Solo drive male rotation Motor power (KW) |

Equipment weight(KG) |

Overall dimension(mm) |

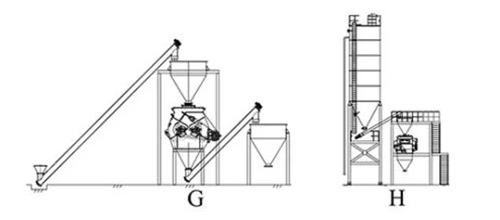

KB1 |

B1 |

A1 |

K1 |

KF1 |

|

|

VSH-0.01 |

4-6L |

130/3 |

0.37 |

N/A |

100 |

455(D)*540(H) |

N/A |

478 |

N/A |

N/A |

N/A |

|

|

VSH-0.015 |

6-9L |

130/3 |

0.37 |

N/A |

110 |

470(D)*563(H) |

N/A |

478 |

N/A |

N/A |

N/A |

|

|

VSH-0.02 |

8-12L |

130/3 |

0.55 |

N/A |

120 |

492(D)*583(H) |

N/A |

478 |

N/A |

N/A |

N/A |

|

|

VSH-0.03 |

12-18L |

130/3 |

0.55 |

N/A |

130 |

524(D)*620(H) |

N/A |

590 |

N/A |

N/A |

N/A |

|

|

VSH-0.05 |

20-30L |

130/3 |

0.75 |

N/A |

150 |

587(D)*724(H) |

N/A |

590 |

N/A |

N/A |

N/A |

|

|

VSH-0.1 |

40-60L |

130/3 |

1.5 |

N/A |

210 |

708(D)*865(H) |

N/A |

682 |

N/A |

N/A |

N/A |

|

|

VSH-0.15 |

60-90L |

130/3 |

1.5 |

N/A |

250 |

782(D)*980(H) |

N/A |

682 |

N/A |

N/A |

N/A |

|

|

VSH-0.2 |

80-120L |

130/3 |

2.2 |

0.37 |

500 |

888(D)*1053(H) |

N/A |

855 |

N/A |

515 |

650 |

|

|

VSH-0.3 |

120-180L |

130/3 |

3 |

0.37 |

550 |

990(D)*1220(H) |

N/A |

855 |

N/A |

515 |

650 |

|

|

VSH-0.5 |

200-300L |

130/3 |

3 |

0.37 |

600 |

1156(D)*1490(H) |

N/A |

855 |

N/A |

515 |

650 |

|

|

VSH-0.8 |

320-480L |

57/2 |

4 |

0.75 |

900 |

1492(D)*1710(H) |

708 |

1005 |

525 |

680 |

890 |

|

|

VSH-1 |

400-600L |

57/2 |

4 |

0.75 |

1200 |

1600(D)*1885(H) |

708 |

1005 |

525 |

680 |

890 |

|

|

VSH-1.5 |

600-900L |

57/2 |

5.5 |

0.75 |

1350 |

1780(D)*2178(H) |

708 |

1025 |

525 |

680 |

890 |

|

|

VSH-2 |

0.8-1.2m3 |

57/2 |

5.5 |

0.75 |

1500 |

1948(D)*2454(H) |

708 |

1025 |

525 |

680 |

890 |

|

|

VSH-2.5 |

1-1.5m3 |

57/2 |

7.5 |

1.1 |

1800 |

2062(D)*2473(H) |

708 |

1075 |

525 |

680 |

890 |

|

|

VSH-3 |

1.2-1.8m3 |

57/2 |

7.5 |

1.1 |

2100 |

2175(D)*2660(H) |

708 |

1075 |

525 |

680 |

890 |

|

|

VSH-4 |

1.6-2.4m3 |

41/1.3 |

11 |

1.5 |

2500 |

2435(D)*3071(H) |

730 |

1295 |

N/A |

856 |

1000 |

|

|

VSH-5 |

2-3m3 |

41/1.3 |

15 |

1.5 |

3000 |

2578(D)*3306(H) |

730 |

1415 |

N/A |

856 |

1000 |

|

|

VSH-6 |

2.4-3.6m3 |

41/1.3 |

15 |

1.5 |

3500 |

2715(D)*3521(H) |

730 |

1415 |

N/A |

856 |

1000 |

|

|

VSH-8 |

3.2-4.8m3 |

41/1.1 |

18.5 |

3 |

3800 |

2798(D)*3897(H) |

835 |

1480 |

780 |

N/A |

N/A |

|

|

VSH-10 |

4-6m3 |

41/1.1 |

18.5 |

3 |

4300 |

3000(D)*4192(H) |

835 |

1480 |

780 |

N/A |

N/A |

|

|

VSH-12 |

4.8-7.2m3 |

41/1.1 |

22 |

3 |

4500 |

3195(D)*4498(H) |

835 |

1480 |

780 |

N/A |

N/A |

|

|

VSH-15 |

6-9m3 |

41/0.8 |

30 |

4 |

5000 |

3434(D)*4762(H) |

N/A |

1865 |

1065 |

N/A |

N/A |

|

|

VSH-20 |

8-12m3 |

41/0.8 |

30 |

4 |

5500 |

3760(D)*5288(H) |

N/A |

1865 |

1065 |

N/A |

N/A |

|

|

VSH-25 |

10-15m3 |

41/0.8 |

37 |

5.5 |

6200 |

4032(D)*5756(H) |

N/A |

N/A |

1065 |

N/A |

N/A |

|

|

VSH-30 |

12-18m3 |

41/0.8 |

45 |

5.5 |

6700 |

4278(D)*6072(H) |

N/A |

N/A |

1065 |

N/A |

N/A |

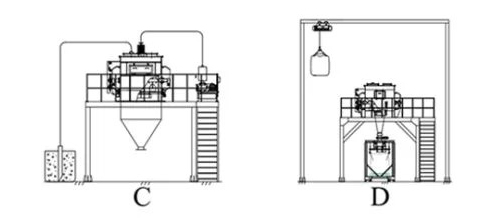

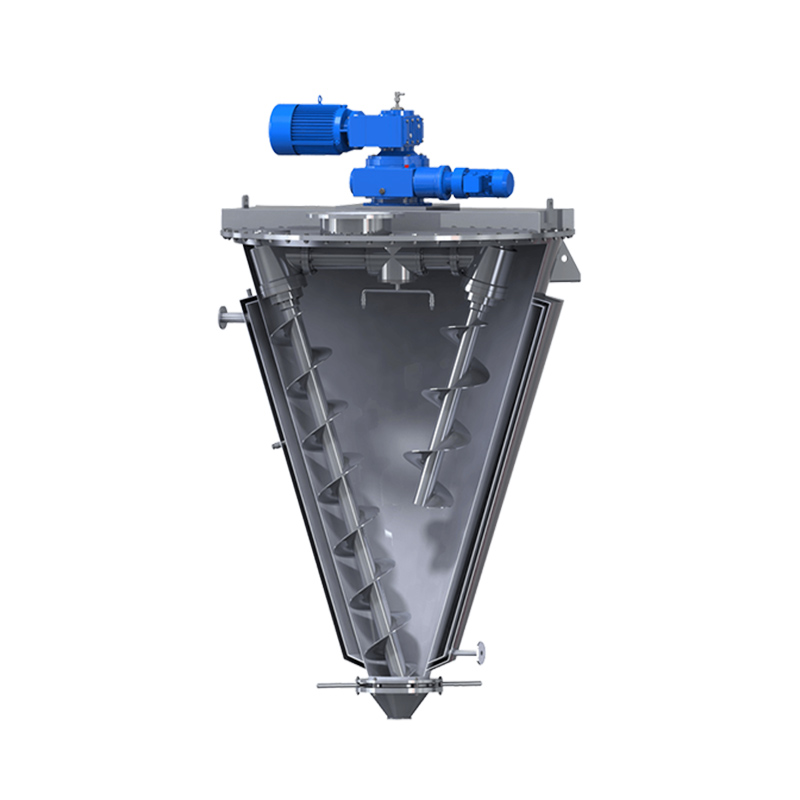

Conical Screw Mixer

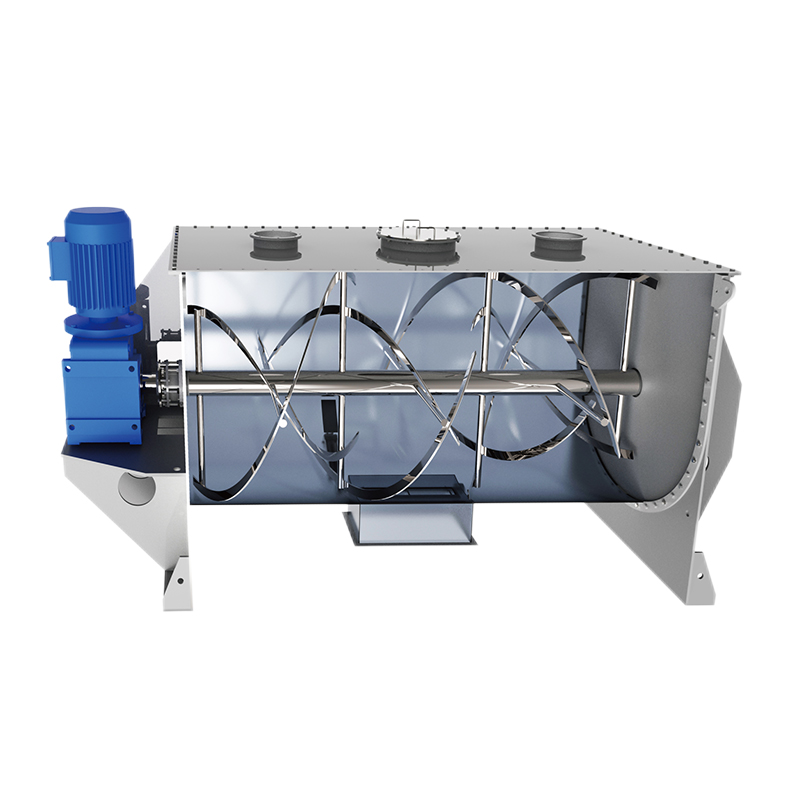

Conical Screw Mixer Conical Screw Belt Mixer

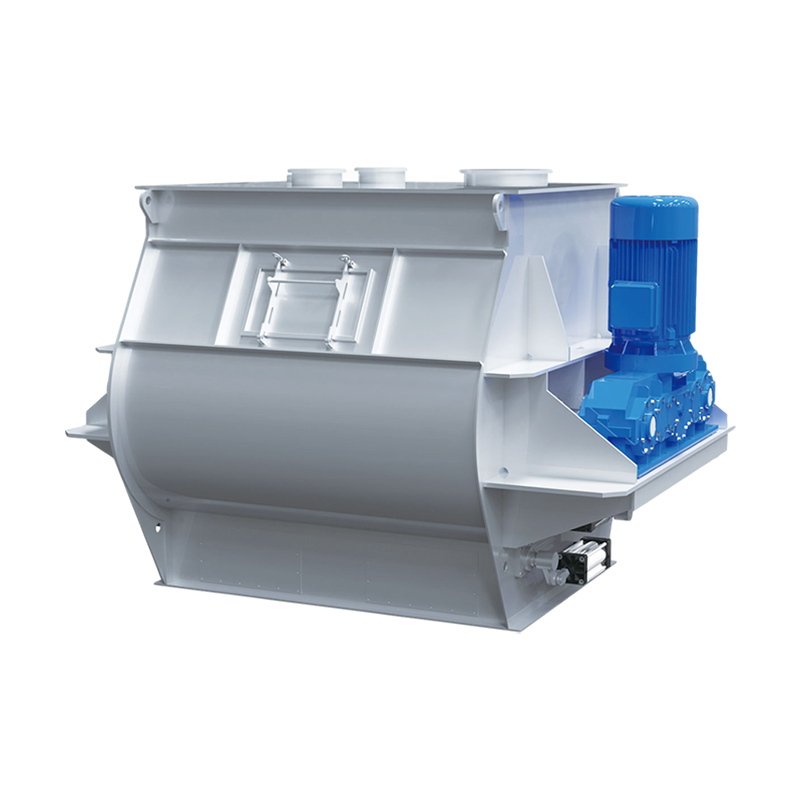

Conical Screw Belt Mixer Ribbon Blender

Ribbon Blender Plough-shear Mixer

Plough-shear Mixer Double Shaft Paddle Mixer

Double Shaft Paddle Mixer CM Series Mixer

CM Series Mixer