Weighing Module Components: 3 or 4 weighing modules are installed at the bottom of the equipment's ear brackets. The output from the modules goes to a junction box, which interfaces with the weighing indicator.

The enterprise standard indicator is installed using an embedded rail system inside the cabinet. If it needs to be placed on the cabinet door, it should be specified when ordering.

The indicator can achieve a precision of one part in one hundred thousand, and is typically set for use at C3, 1/3000 accuracy.

Weighing Module Selection: (Equipment weight + Material weight) * 2 / Number of modules (3 or 4) = Range selection for each module.

Introducing our state-of-the-art weighing modules designed to provide accurate and reliable weight measurement for a variety of industrial applications. These modules are designed to deliver precise results, ensuring your operations are efficient and productive.

Our weighing modules are equipped with advanced technology and high-quality materials, making them suitable for use in demanding environments. Whether you need to weigh heavy objects or delicate materials, our modules can meet your specific requirements with accuracy and consistency.

Focused on durability and performance, our weigh modules are built to withstand the rigors of industrial use. They provide reliable measurements even under challenging conditions, ensuring you can trust the accuracy of your results every time.

In addition to their robust construction, our weighing modules are designed to be easily installed and integrated into existing systems. This enables seamless implementation and minimizes downtime, so you can start benefiting from its capabilities immediately.

Our weighing modules are suitable for a wide range of applications, including manufacturing, logistics and material handling. Whether you need to monitor inventory, ensure product quality, or optimize production processes, our modules provide the accuracy and reliability you need to make informed decisions and drive operational excellence.

At the heart of our weighing modules is a commitment to quality and performance. We understand the importance of accurate weight measurement in industrial environments, and our modules are designed to deliver consistent results you can rely on.

Experience the difference our weighing modules can make in your operation. With their accuracy, durability and ease of integration, they are the ideal solution for your weighing needs. Trust our weighing modules to increase the efficiency and accuracy of your processes and take your operations to the next level.

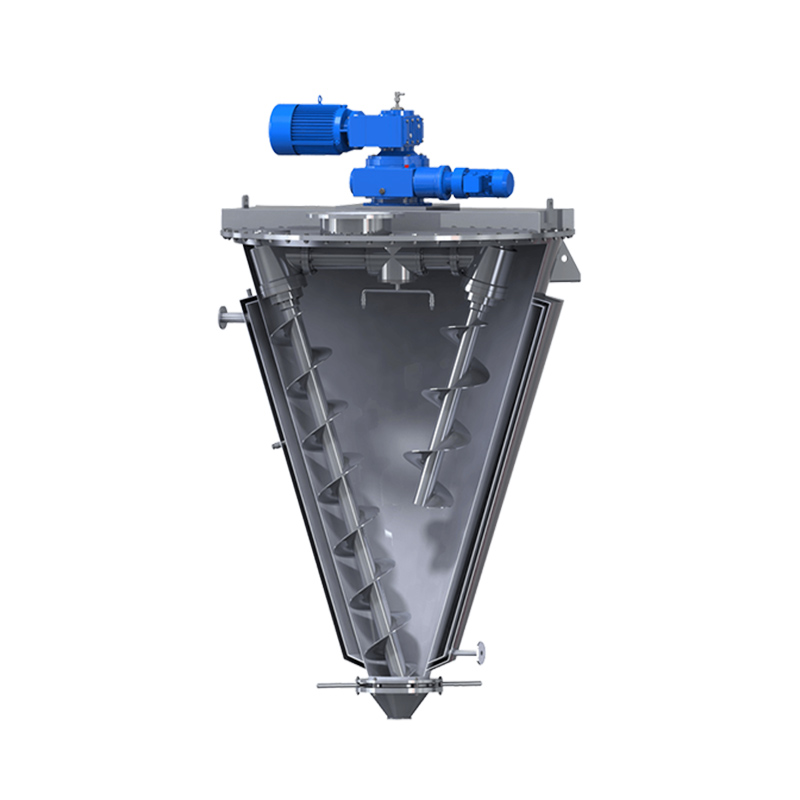

Conical Screw Mixer

Conical Screw Mixer Conical Screw Belt Mixer

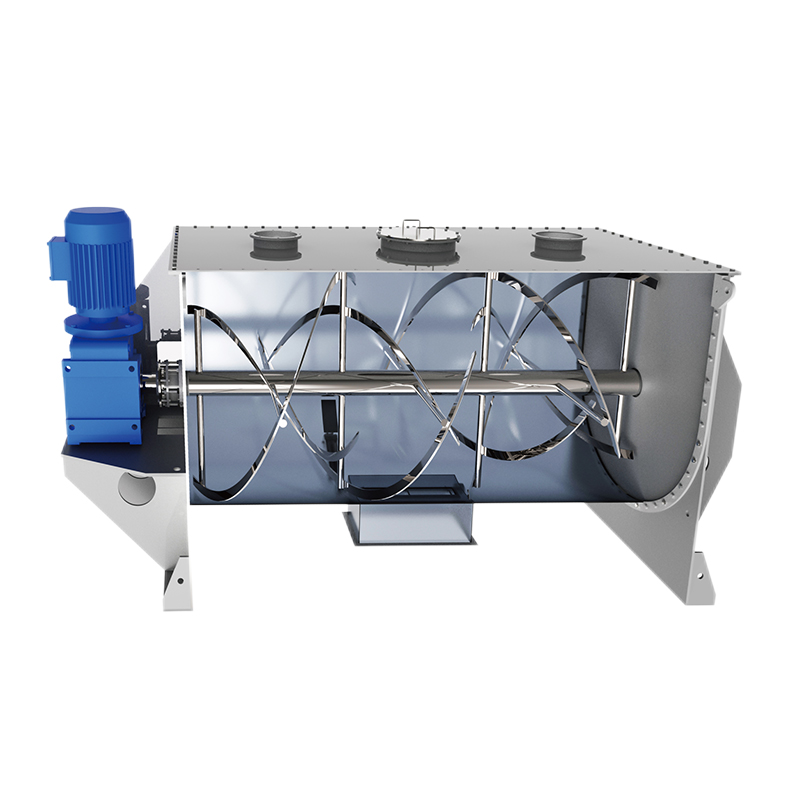

Conical Screw Belt Mixer Ribbon Blender

Ribbon Blender Plough-shear Mixer

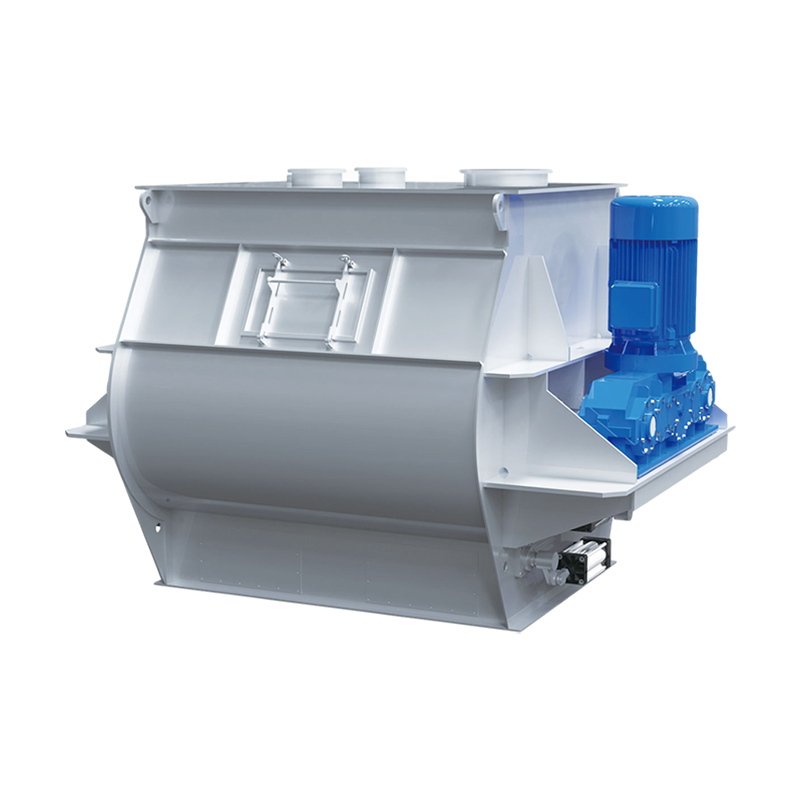

Plough-shear Mixer Double Shaft Paddle Mixer

Double Shaft Paddle Mixer CM Series Mixer

CM Series Mixer