Industrial Double Shaft Paddle Mixer

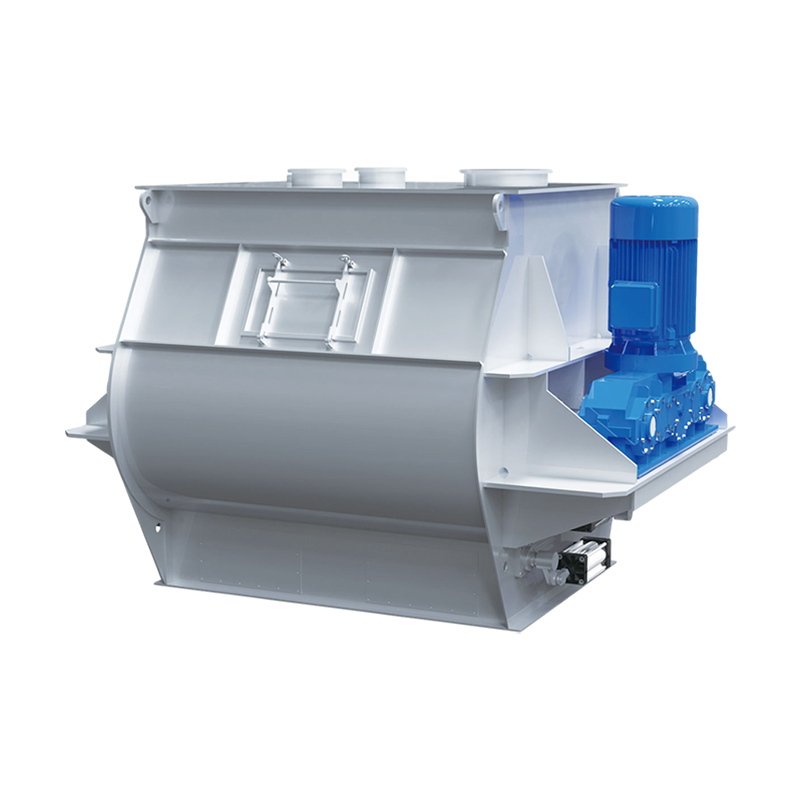

Description

Equipment Specifications

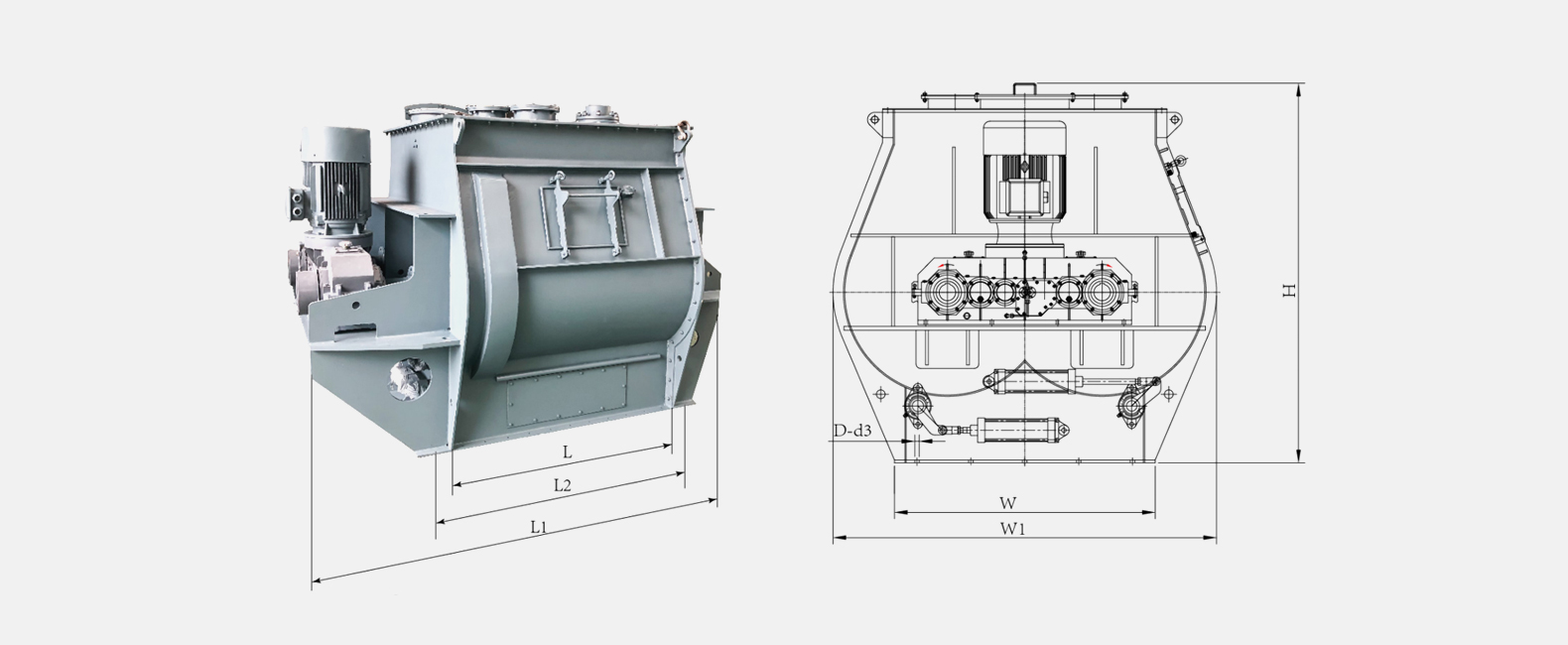

Product Parameters

|

Model |

Allowable working volume |

Spindle speed(RPM) |

Motor power (KW) |

Equipment weight(KG) |

Overall dimension(mm) |

|||||||

|

L |

W |

H |

L1 |

L2 |

W1 |

W2 |

D-d3 |

|||||

|

SYJW-0.5 |

100-300L |

51 |

5.5/7.5 |

850 |

800 |

1150 |

1300 |

1620 |

880 |

1295 |

1539 |

2-5x⌀18 |

|

SYJW-1 |

200-600L |

51 |

11 |

1500 |

1200 |

1210 |

1430 |

2100 |

1320 |

1394 |

1700 |

2-5x⌀22 |

|

SYJW-2 |

600-1200L |

38 |

18.5 |

2250 |

1470 |

1200 |

1790 |

2550 |

1620 |

1632 |

2180 |

2-5x⌀22 |

|

SYJW-3 |

0.6-1.8m3 |

30 |

22/30 |

3350 |

1500 |

1600 |

1985 |

2650 |

1700 |

2042 |

2650 |

2-5x⌀24 |

|

SYJW-4 |

0.8-2.4m3 |

30 |

30 |

4500 |

1700 |

1600 |

1985 |

2860 |

1900 |

2042 |

2730 |

2-5x⌀24 |

|

SYJW-5 |

1-3m3 |

30 |

37 |

5000 |

2000 |

1600 |

2060 |

3160 |

2200 |

2086 |

2780 |

2-5x⌀24 |

|

SYJW-6 |

1.2-3.6m3 |

30 |

37 |

5500 |

2100 |

1500 |

2183 |

3500 |

2250 |

2206 |

2900 |

2-5x⌀26 |

|

SYJW-8 |

1.6-4.8m3 |

30 |

45 |

6500 |

2200 |

1830 |

2423 |

3600 |

2400 |

2530 |

3300 |

2-6x⌀26 |

|

SYJW-10 |

2-6m3 |

30 |

55 |

8000 |

2320 |

1980 |

2613 |

3800 |

2520 |

2780 |

3600 |

2-6x⌀26 |

|

SYJW-12 |

2.4-7.2m3 |

30 |

75 |

8900 |

2600 |

2800 |

2683 |

4100 |

2800 |

2870 |

3700 |

2-6x⌀26 |

|

SYJW-15 |

3-9m3 |

26 |

90 |

10500 |

2800 |

2180 |

2815 |

4400 |

3000 |

3164 |

4000 |

2-6x⌀26 |

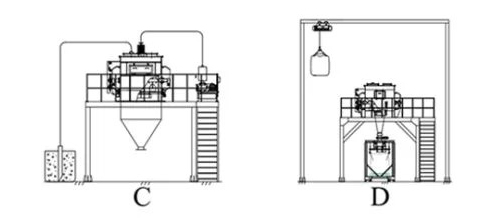

Conical Screw Mixer

Conical Screw Mixer Conical Screw Belt Mixer

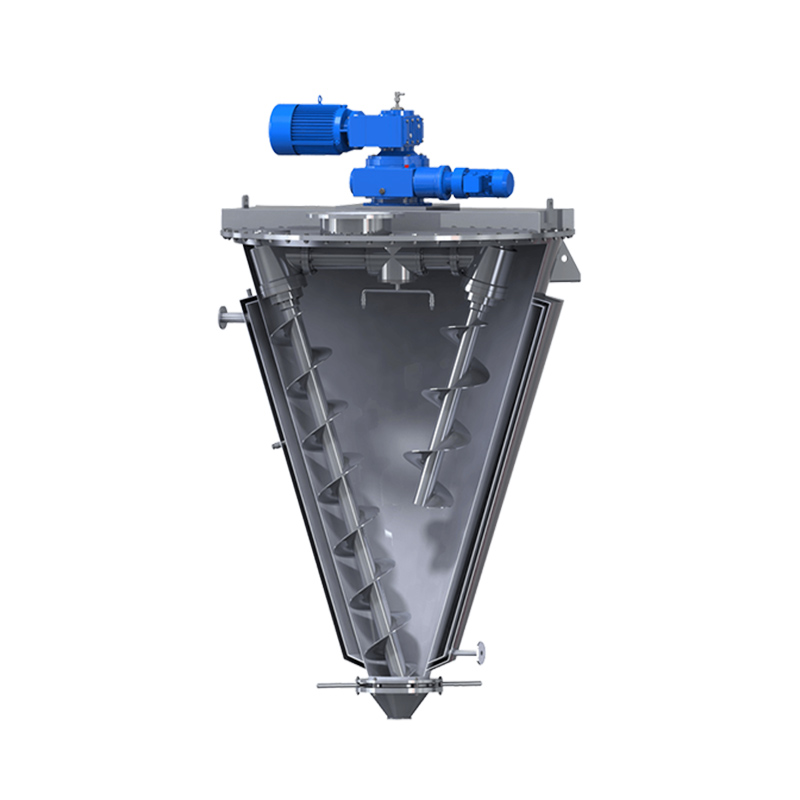

Conical Screw Belt Mixer Ribbon Blender

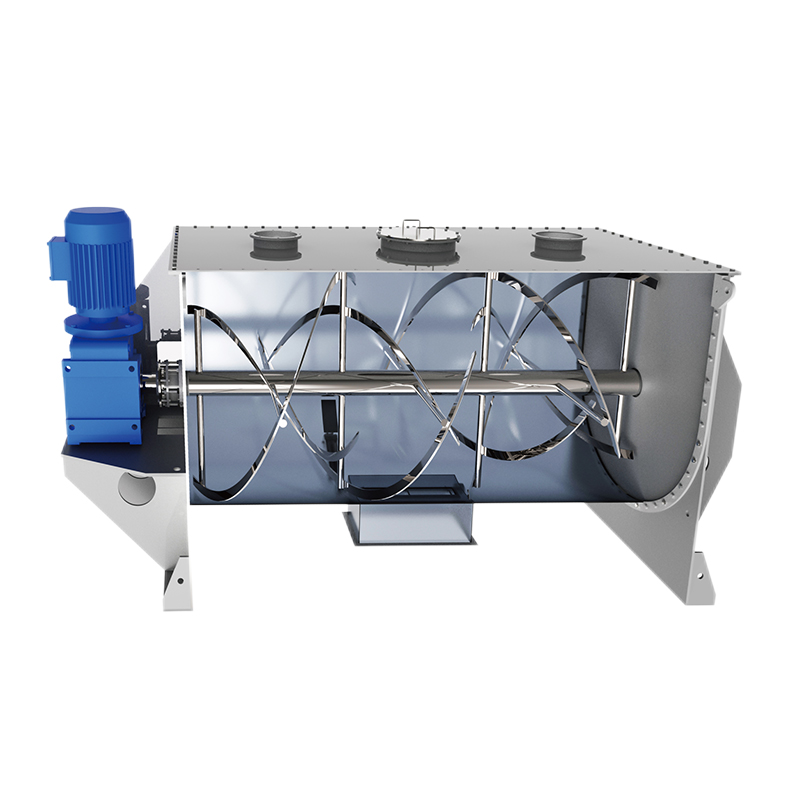

Ribbon Blender Plough-shear Mixer

Plough-shear Mixer Double Shaft Paddle Mixer

Double Shaft Paddle Mixer CM Series Mixer

CM Series Mixer