01

High-Quality Ribbon Blender for Sale

01

Classic hybrid model.

02

Excellent mixing uniformity.

03

Exquisite design and meticulous craftsmanship.

APPLICATION

Chemical, fertilizer, agricultural (veterinary) chemicals, feed, refractory materials, construction materials, dry powder mortar, metallurgy, refining, dyes, additives, batteries, electronic plastics, ceramics, glazing, glass, food, pharmaceuticals, and other fields for the mixing of powder to powder, and powder to liquid (small amounts).

Equipment Specifications

| Equipment Capacity | 0.1m³ to 60m³ |

| Range of Batch Processing Volume | 60 liters to 35m³ |

| Range of Batch Processing Weight | 30kg to 40 tons |

| Material Options | Stainless Steel 304, 316L, 321, Carbon Steel, Manganese Steel, Hardox450, JFE450, and other specified materials. |

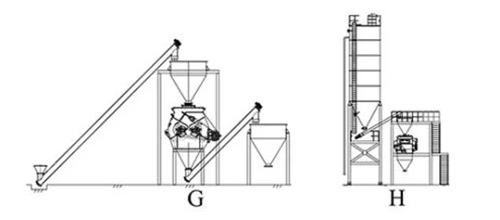

Product Parameters

| Model | Allowable working volume | Spindle speed(RPM) | Motor power(KW) | Equipment weight(KG) | Size of discharge opening(mm) | Overall dimension(mm) | Inlet size(mm) | |||||||

| L | W | H | L1 | L2 | W1 | d3 | N1 | N2 | ||||||

| SYLW-0.1 | 30-60L | 76 | 2.2 | 250 | 240*80 | 700 | 436 | 613 | 1250 | 750 | 840 | ⌀14 | / | / |

| SYLW-0.2 | 60-120L | 66 | 4 | 380 | 240*80 | 900 | 590 | 785 | 1594 | 980 | 937 | ⌀18 | / | / |

| SYLW-0.3 | 90-180L | 66 | 4 | 600 | 240*80 | 980 | 648 | 1015 | 1630 | 1060 | 1005 | ⌀18 | / | ⌀400 |

| SYLW-0.5 | 150-300L | 63 | 7.5 | 850 | 240*80 | 1240 | 728 | 1140 | 2030 | 1340 | 1175 | ⌀18 | / | ⌀500 |

| SYLW-1 | 300-600L | 41 | 11 | 1300 | 360*120 | 1500 | 960 | 1375 | 2460 | 1620 | 1455 | ⌀22 | ⌀300 | ⌀500 |

| SYLW-1.5 | 450-900L | 33 | 15 | 1800 | 360*120 | 1800 | 1030 | 1470 | 2775 | 1920 | 1635 | ⌀26 | ⌀300 | ⌀500 |

| SYLW-2 | 0.6-1.2m3 | 33 | 18.5 | 2300 | 360*120 | 2000 | 1132 | 1545 | 3050 | 2120 | 1710 | ⌀26 | ⌀300 | ⌀500 |

| SYLW-3 | 0.9-1.8m3 | 29 | 22 | 2750 | 360*120 | 2380 | 1252 | 1680 | 3500 | 2530 | 1865 | ⌀26 | ⌀300 | ⌀500 |

| SYLW-4 | 1.2-2.4m3 | 29 | 30 | 3300 | 500*120 | 2680 | 1372 | 1821 | 3870 | 2880 | 1985 | ⌀26 | ⌀300 | ⌀500 |

| SYLW-5 | 1.5-3m3 | 29 | 37 | 4200 | 500*120 | 2800 | 1496 | 1945 | 4090 | 3000 | 2062 | ⌀26 | ⌀300 | ⌀500 |

| SYLW-6 | 1.8-3.6m3 | 26 | 37 | 5000 | 500*120 | 3000 | 1602 | 2380 | 4250 | 3200 | 1802 | ⌀26 | 2-⌀300 | ⌀500 |

| SYLW-8 | 2.4-4.8m3 | 26 | 45 | 6300 | 700*140 | 3300 | 1756 | 2504 | 4590 | 3500 | 1956 | ⌀26 | 2-⌀300 | ⌀500 |

| SYLW-10 | 3-6m3 | 23 | 55 | 7500 | 700*140 | 3600 | 1816 | 2800 | 5050 | 3840 | 2016 | ⌀26 | 2-⌀300 | ⌀500 |

| SYLW-12 | 3.6-7.2m3 | 19 | 55 | 8800 | 700*140 | 4000 | 1880 | 2753 | 5500 | 4240 | 2160 | ⌀26 | 2-⌀300 | ⌀500 |

| SYLW-15 | 4.5-9m3 | 17 | 55 | 9800 | 700*140 | 4500 | 1960 | 2910 | 5900 | 4720 | 2170 | ⌀26 | 2-⌀300 | ⌀500 |

| SYLW-20 | 6-12m3 | 15 | 75 | 12100 | 700*140 | 4500 | 2424 | 2830 | 7180 | 4740 | 2690 | ⌀26 | 2-⌀300 | ⌀500 |

| SYLW-25 | 7.5-15m3 | 15 | 90 | 16500 | 700*140 | 4800 | 2544 | 3100 | 7990 | 5020 | 2730 | ⌀26 | 2-⌀300 | ⌀500 |

| SYLW-20 | 9-18m3 | 13 | 110 | 17800 | 700*140 | 5100 | 2624 | 3300 | 8450 | 5350 | 2860 | ⌀32 | 2-⌀300 | ⌀500 |

| SYLW-35 | 10.5-21m3 | 11 | 110 | 19800 | 700*140 | 5500 | 2825 | 3350 | 8600 | 5500 | 2950 | ⌀40 | 2-⌀300 | ⌀500 |

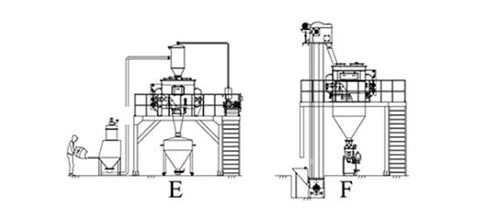

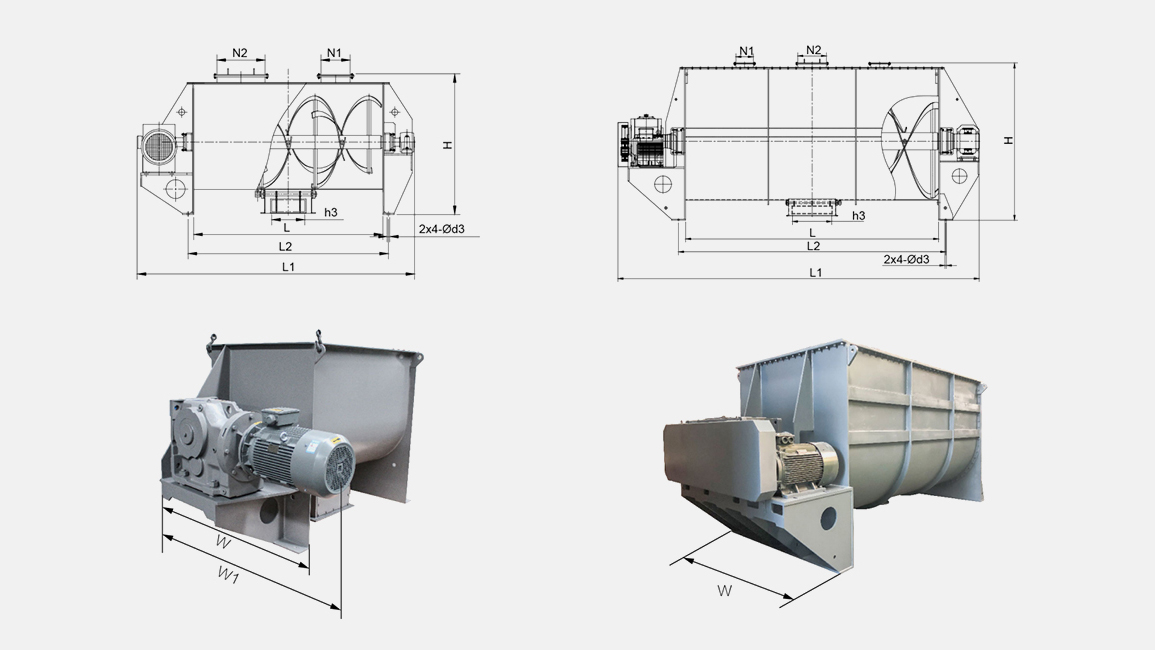

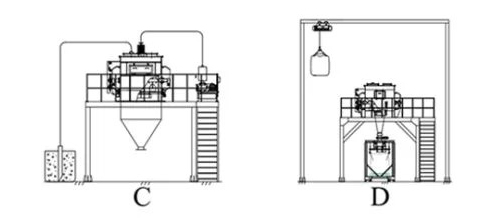

Configuration A: forklift feeding → manual feeding to the mixer → mixing → manual packaging (weighing scale weighing)

Configuration B: crane feeding → manual feeding to the feeding station with dust removal → mixing → planetary discharge valve uniform speed discharge → vibrating screen

Configuration C: continuous vacuum feeder suction feeding → mixing → silo

Configuration D: ton package lifting feeding → mixing → straight ton package packaging

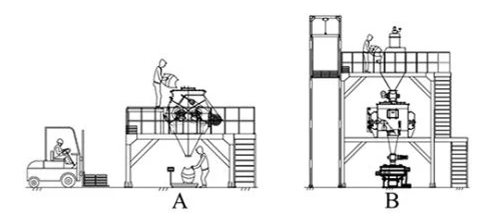

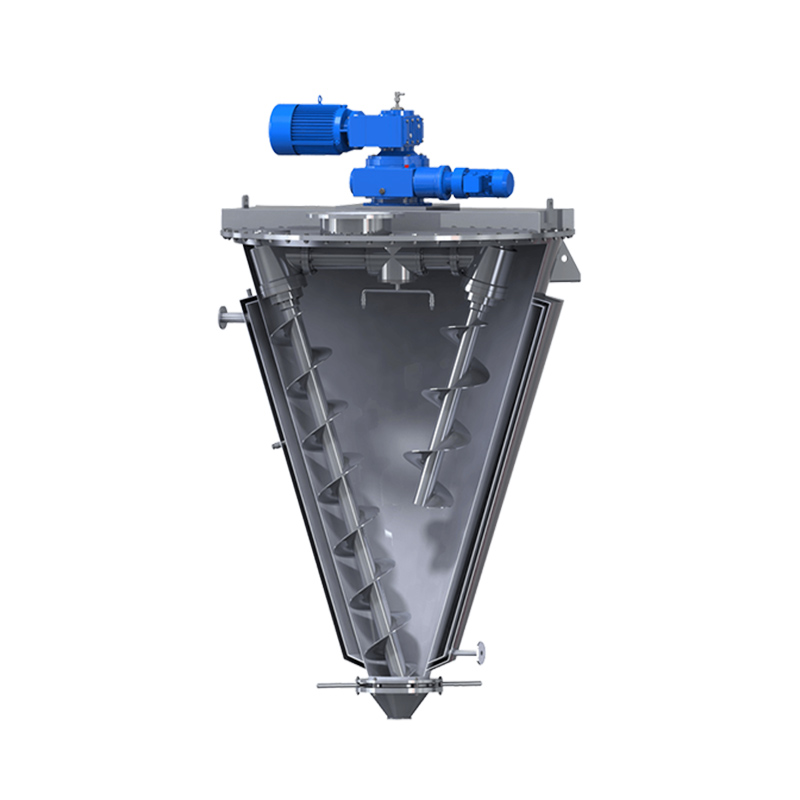

Conical Screw Mixer

Conical Screw Mixer Conical Screw Belt Mixer

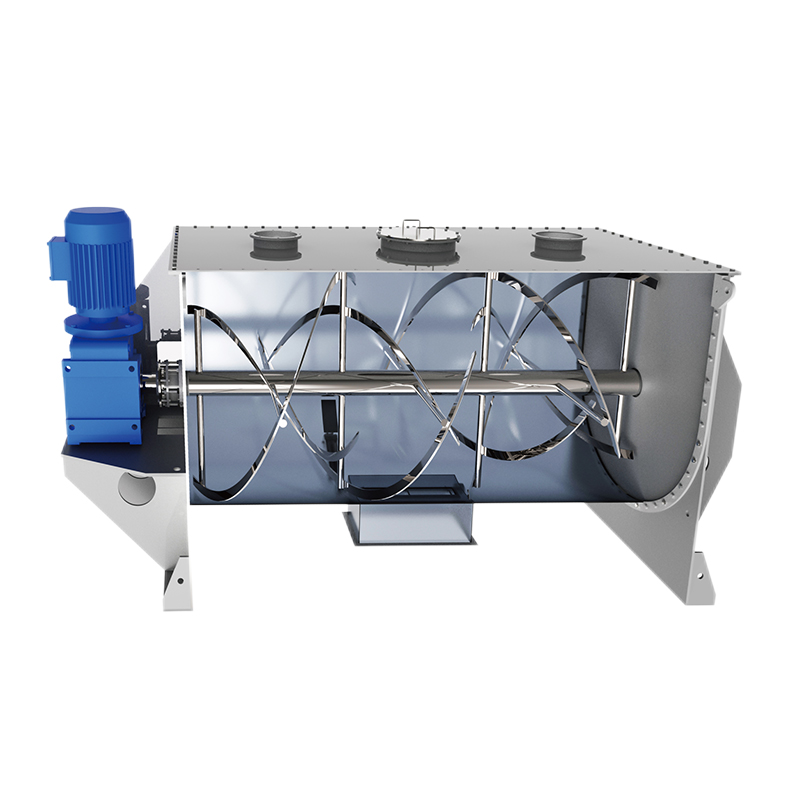

Conical Screw Belt Mixer Ribbon Blender

Ribbon Blender Plough-shear Mixer

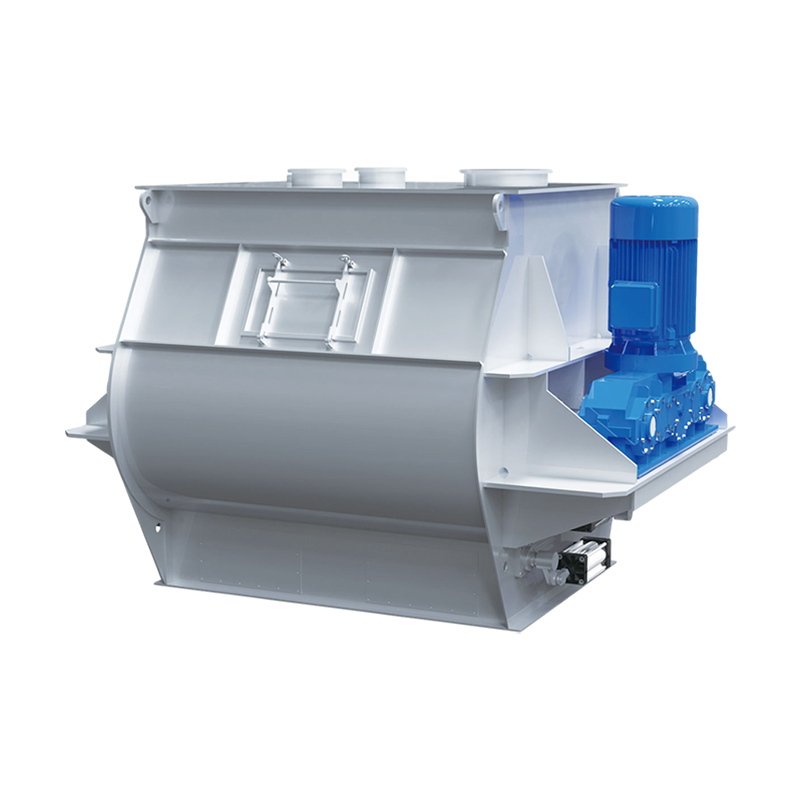

Plough-shear Mixer Double Shaft Paddle Mixer

Double Shaft Paddle Mixer CM Series Mixer

CM Series Mixer