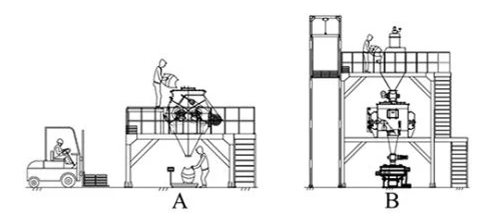

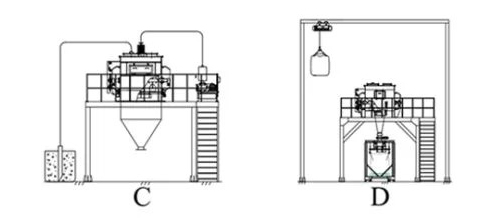

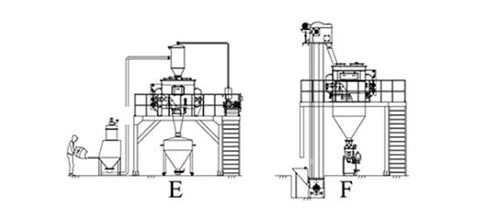

SYLD series-plough-shear mixer is a special horizontal mixer which is suitable for mixing materials easy to be agglomerated (such as fiber or easy to be agglomerated by moisture), mixing powder materials with poor fluidity, mixing viscous materials, mixing powder with liquid agglomeration and mixing low-viscosity fluids. In the spindle mixer and auxiliary fly cutter powerful shear mixing effect, complete the excellent mixing production. Widely used in ceramic clay, refractory materials, wear-resistant materials, cemented carbide, food additives, ready-mixed mortar, composting technology, sludge treatment, rubber and plastic, fire-fighting chemicals, special building materials and other industries.

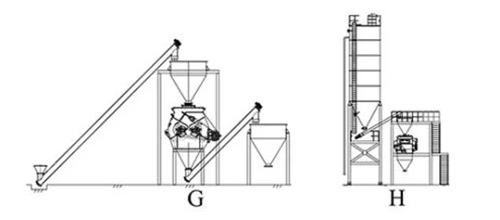

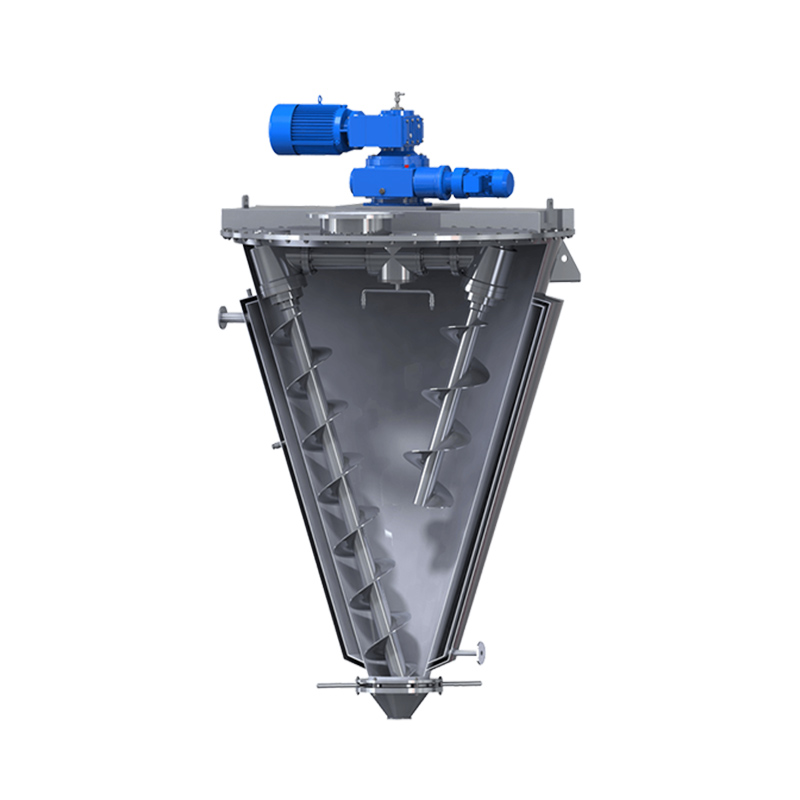

Conical Screw Mixer

Conical Screw Mixer Conical Screw Belt Mixer

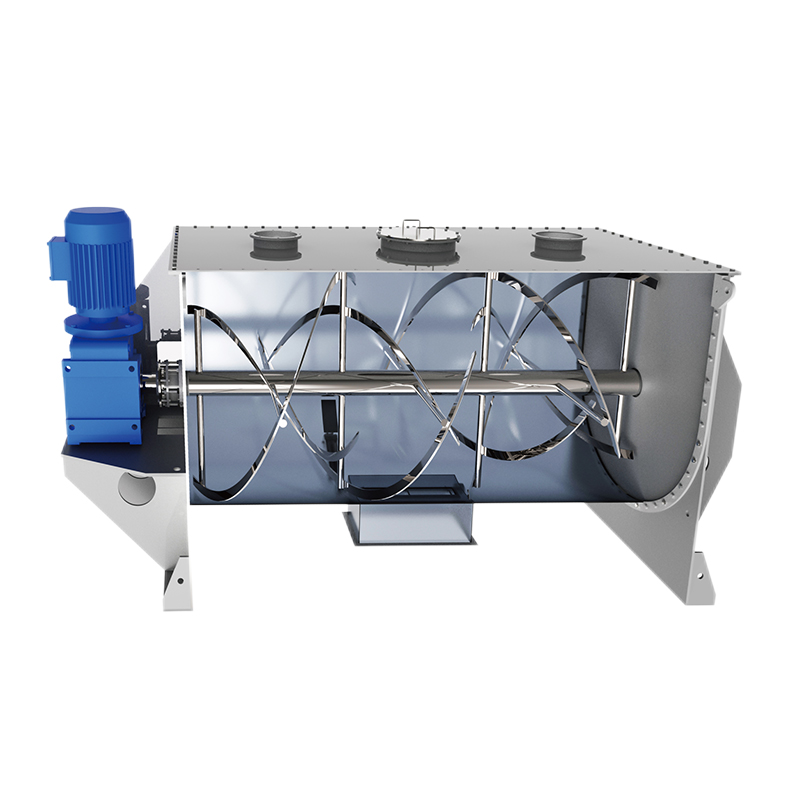

Conical Screw Belt Mixer Ribbon Blender

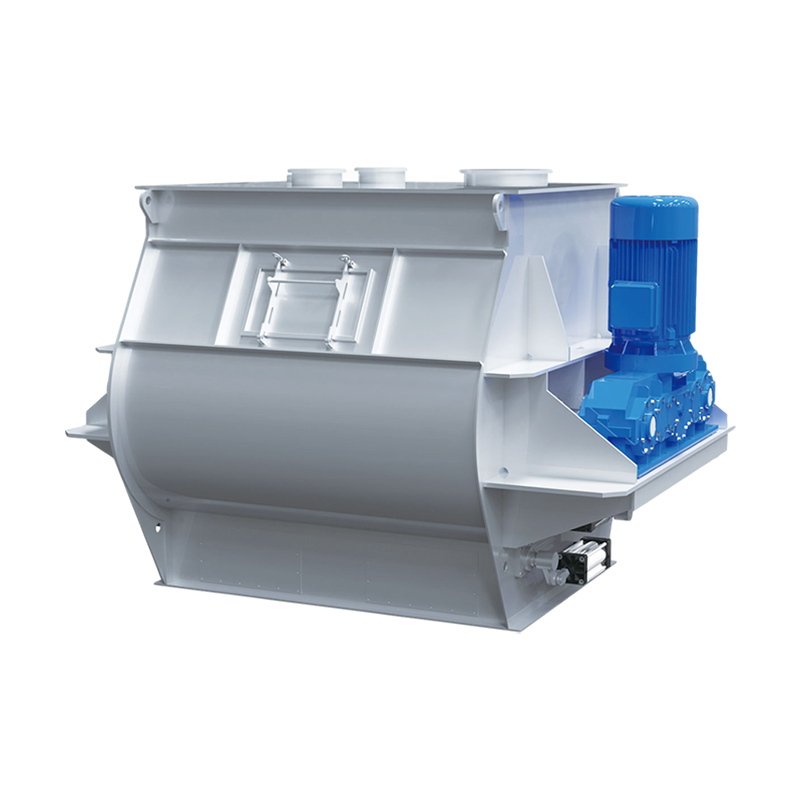

Ribbon Blender Plough-shear Mixer

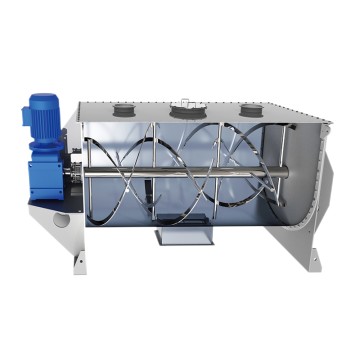

Plough-shear Mixer Double Shaft Paddle Mixer

Double Shaft Paddle Mixer CM Series Mixer

CM Series Mixer