01

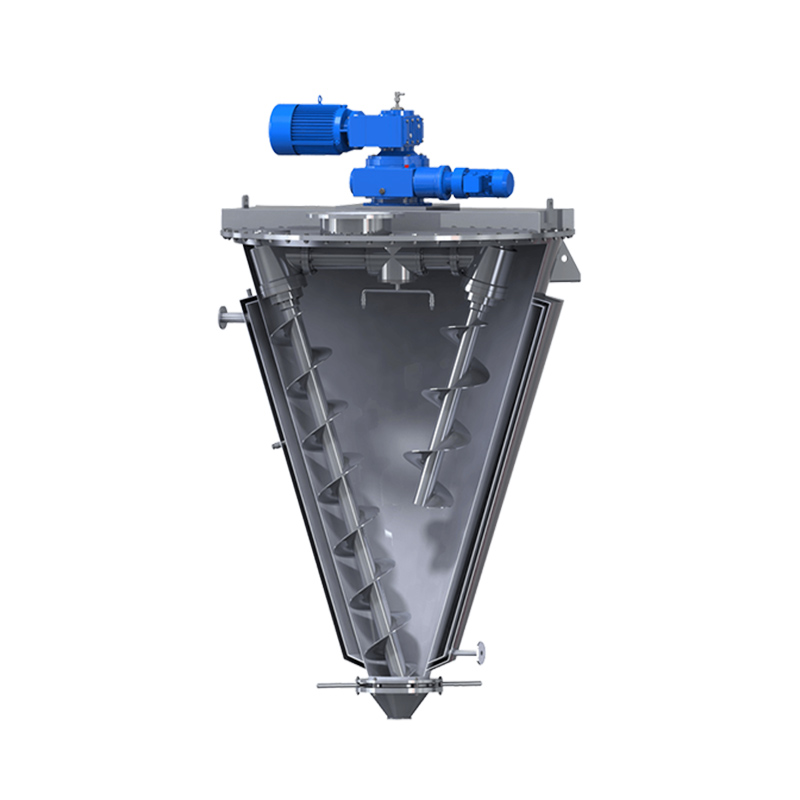

High-Performance Conical Screw Belt Mixer

Description

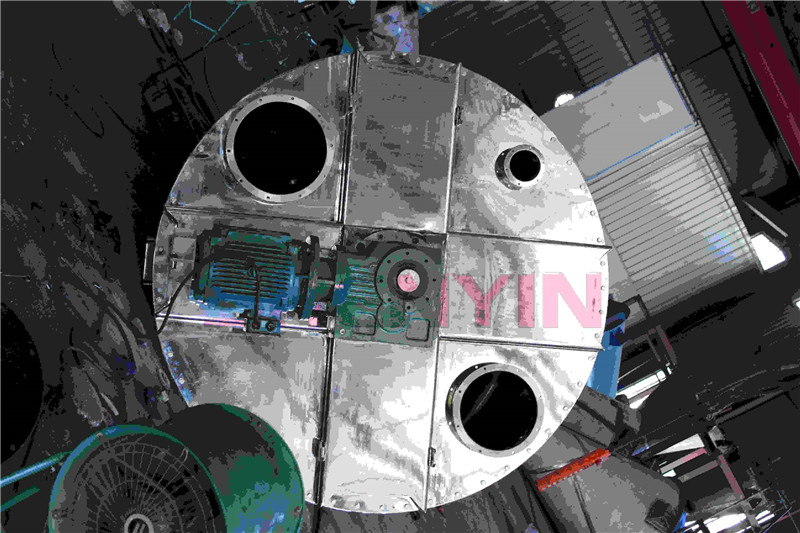

Compared with the same conical mixer VSH series, VJ series - conical screw mixer cylinder without transmission parts, and conical vertical cylinder and the bottom of the discharge structure to ensure that the cylinder material "zero" residue, to meet the food, pharmaceutical-grade (cGMP standard) mixing production of ultra-high hygiene requirements, and is therefore called by the customer! It is also called "cone" sanitary mixer by customers.

The mixer has been widely used in all walks of life, especially by the food, medicine and other health requirements of the customer's favor; In addition, the mixer in addition to powder + powder mixing, powder + liquid (a small amount of) mixing production, in the mixing of some low-viscosity fluids in the production of the production of a very good applicability.

Product Parameters

|

Model |

Allowable working volume |

Spindle speed(RPM) |

Motor power (KW)

|

Equipment weight(KG) |

Overall dimension(mm) |

|

VJ-0.1 |

70L |

85 |

1.5-2.2 |

180 |

692(D)*1420(H) |

|

VJ-0.2 |

140L |

63 |

3 |

260 |

888(D)*1266(H) |

|

VJ-0.3 |

210L |

63 |

3-5.5 |

460 |

990(D)*1451(H) |

|

VJ-0.5 |

350L |

63 |

4-7.5 |

510 |

1156(D)*1900(H) |

|

VJ-0.8 |

560L |

43 |

4-7.5 |

750 |

1492(D)*2062(H) |

|

VJ-1 |

700L |

43 |

7.5-11 |

1020 |

1600(D)*2185(H) |

|

VJ-1.5 |

1.05m3 |

41 |

11-15 |

1100 |

1780(D)*2580(H) |

|

VJ-2 |

1.4m3 |

4 |

15-18.5 |

1270 |

1948(D)*2825(H) |

|

VJ-2.5 |

1.75m3 |

4 |

18.5-22 |

1530 |

2062(D)*3020(H) |

|

VJ-3 |

2.1m3 |

39 |

18.5-22 |

1780 |

2175(D)*3200(H) |

|

VJ-4 |

2.8m3 |

36 |

22 |

2300 |

2435(D)*3867(H) |

|

VJ-6 |

4.2m3 |

33 |

30 |

2700 |

2715(D)*4876(H) |

|

VJ-8 |

5.6m3 |

31 |

37 |

3500 |

2798(D)*5200(H) |

|

VJ-10 |

7m3 |

29 |

37 |

4100 |

3000(D)*5647(H) |

|

VJ-12 |

8.4m3 |

23 |

45 |

4600 |

3195(D)*5987(H) |

|

VJ-15 |

10.5m3 |

19 |

55 |

5300 |

3434(D)*6637(H) |

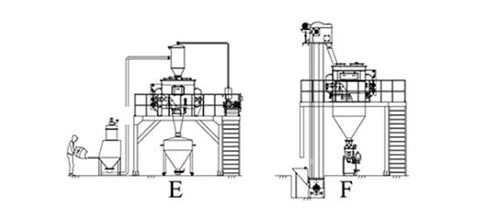

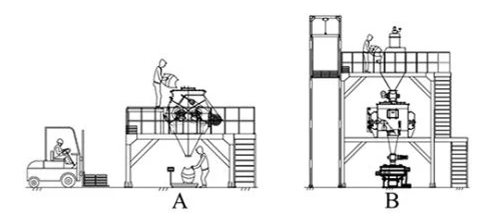

Configuration A: forklift feeding → manual feeding to the mixer → mixing → manual packaging (weighing scale weighing)

Configuration B: crane feeding → manual feeding to the feeding station with dust removal → mixing → planetary discharge valve uniform speed discharge → vibrating screen

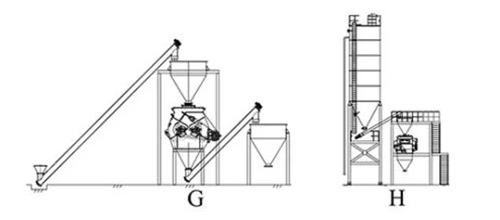

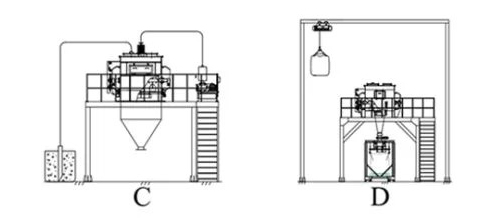

Configuration C: continuous vacuum feeder suction feeding → mixing → silo

Configuration D: ton package lifting feeding → mixing → straight ton package packaging

Conical Screw Mixer

Conical Screw Mixer Conical Screw Belt Mixer

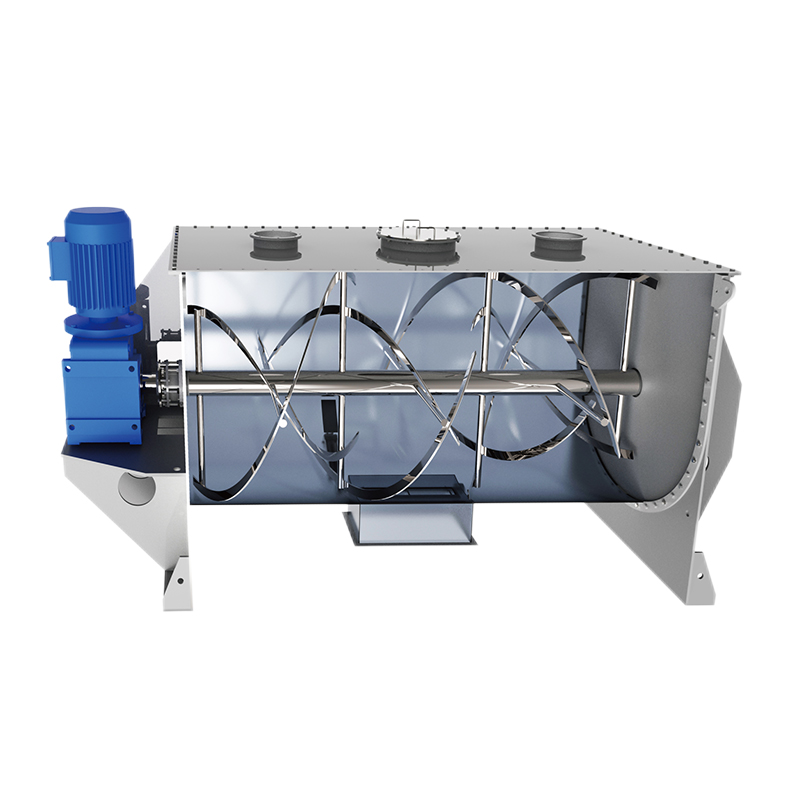

Conical Screw Belt Mixer Ribbon Blender

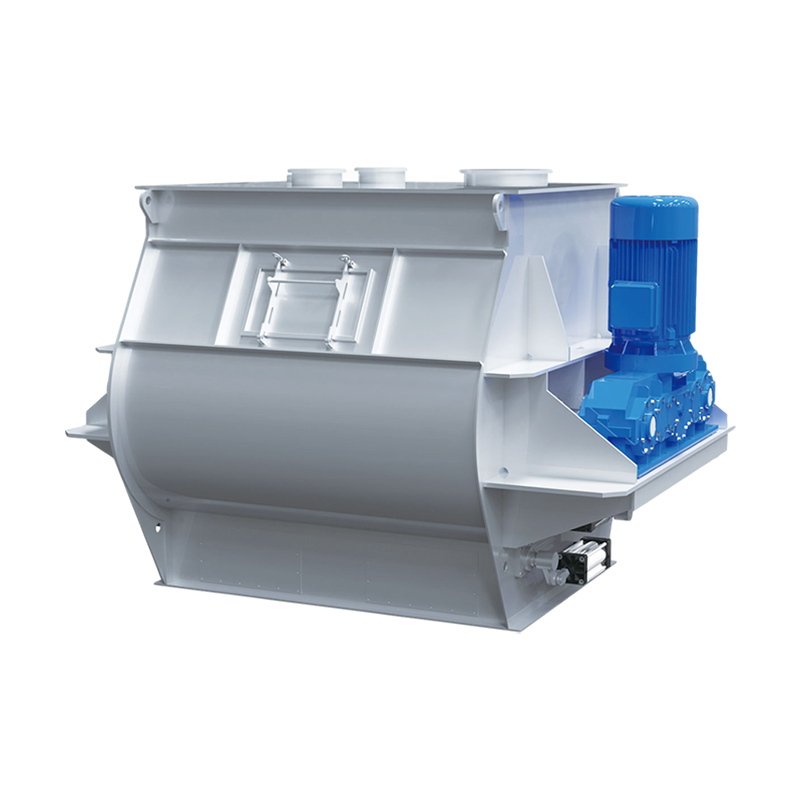

Ribbon Blender Plough-shear Mixer

Plough-shear Mixer Double Shaft Paddle Mixer

Double Shaft Paddle Mixer CM Series Mixer

CM Series Mixer