High-Performance Conical Screw Belt Mixer

Kev piav qhia

Khoom Parameters

| Qauv | Tso cai ua haujlwm ntim | Spindle ceev (RPM) | Lub cev muaj zog (KW)

| Khoom hnyav (KG) | Zuag qhia tag nrho (mm) |

| VJ-0.1 | 70l ua | 85 | 1.5-2.2 | 180 | 692 (D) * 1420 hli |

| VJ-0.2 | 140 L | 63 | 3 | 260 | 888 (D) * 1266 hli |

| VJ-0.3 | 210l ua | 63 | 3-5.5 | 460 | 990 (D) * 1451 hli |

| VJ-0.5 | 350l ua | 63 | 4-7.5 Nws | 510 | 1156 (D) * 1900 hli |

| VJ-0.8 | 560l ua | 43 | 4-7.5 Nws | 750 | 1492 (D) * 2062 hli |

| VJ-1 | 700l ua | 43 | 7.5-11 | 1020 | 1600 (D) * 2185 hli |

| VJ-1.5 | 1,05m ua3 | 41 | 11-15 | 1100 | 1780 (D) * 2580 hli |

| VJ-2 | 1,4m ua3 | 4 | 15-18.5 Nws | 1270 | Xyoo 1948 (D) * 2825 (H) |

| VJ-2.5 | 1,75m ua3 | 4 | 18.5-22.00 Nws | 1530 ib | 2062 (D) * 3020 hli |

| VJ-3 | 2.1m ua3 | 39 | 18.5-22.00 Nws | Xyoo 1780 | 2175 * 3200 hli |

| VJ-4 | 2,8m ua3 | 36 | 22 | 2300 | 2435 * 3867 hli |

| VJ-6 | 4,2m ua3 | 33 | 30 | 2700 ib | 2715 (D) * 4876 hli |

| VJ-8 | 5,6m ua3 | 31 | 37 | 3500 | 2798 (D) * 5200 hli |

| VJ-10 | 7m ua3 | 29 | 37 | 4 100 | 3000 (D) * 5647 (H) |

| VJ-12 | 8,4m ua3 | 23 | 45 | 4600 ib | 3195 (D) * 5987 (H) qhov siab |

| VJ-15 | 10,5m 13 | 19 | 55 | 5300 ib | 3434 (D) * 6637 (H) qhov siab |

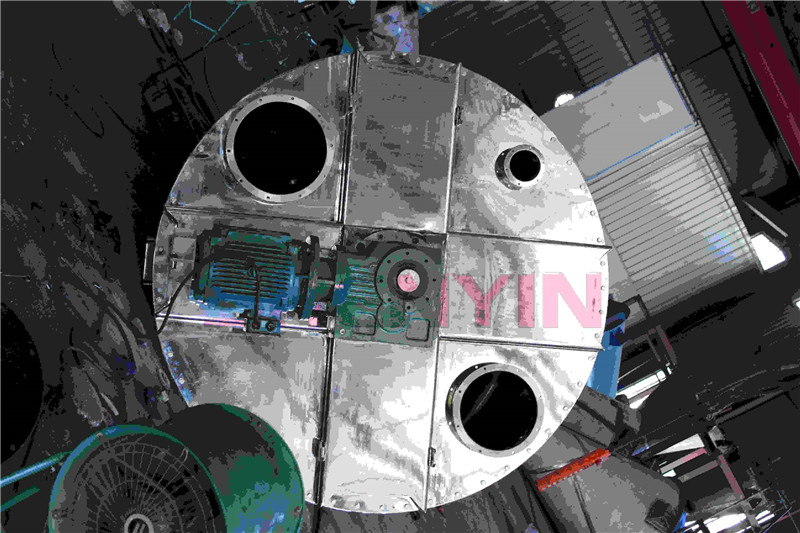

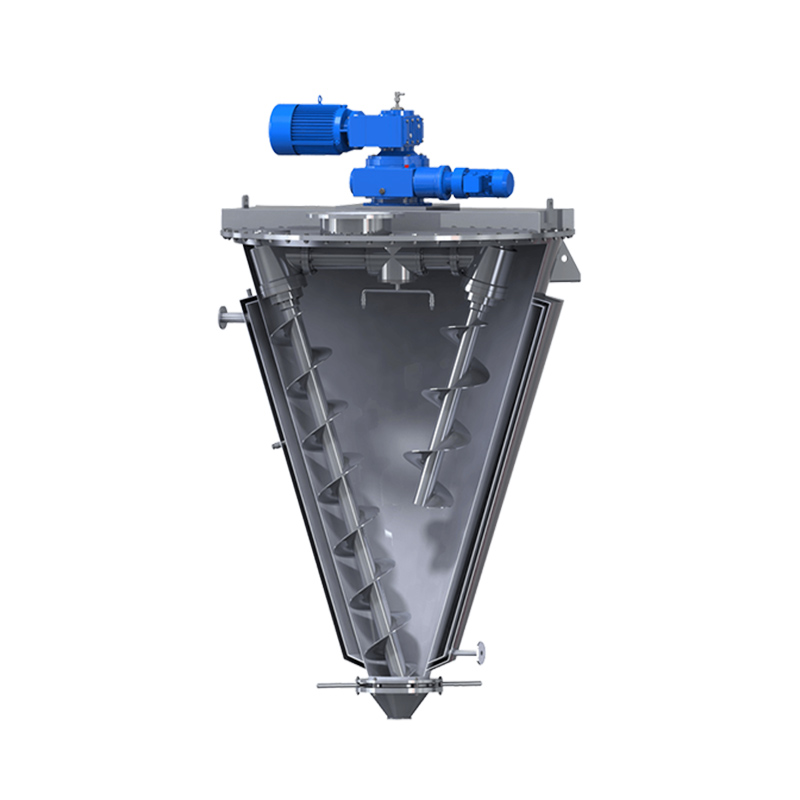

Conical Ntsia Hlau Tov Khoom

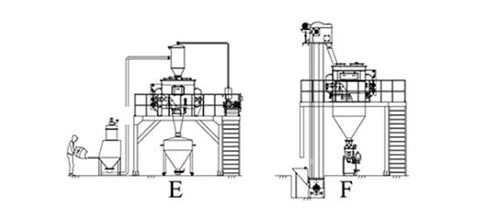

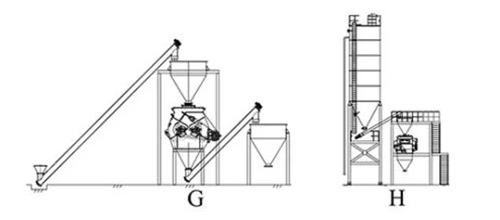

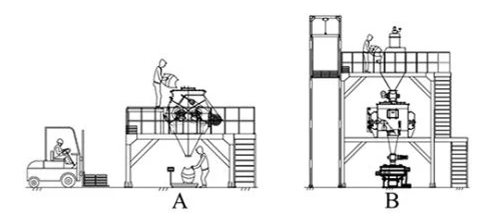

Conical Ntsia Hlau Tov Khoom Conical Screw Belt Mixer

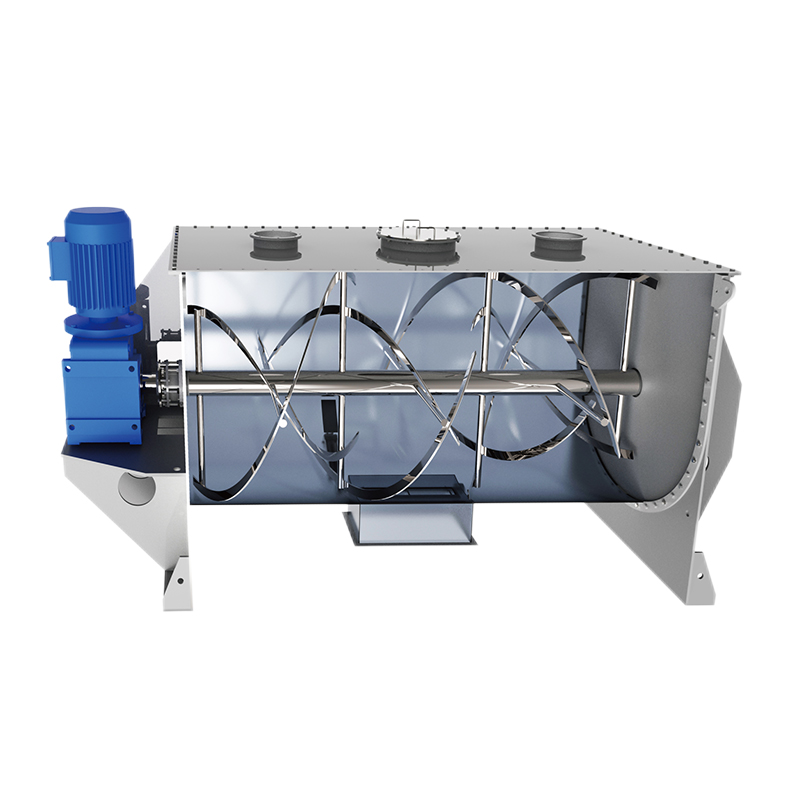

Conical Screw Belt Mixer Ribbon Blender

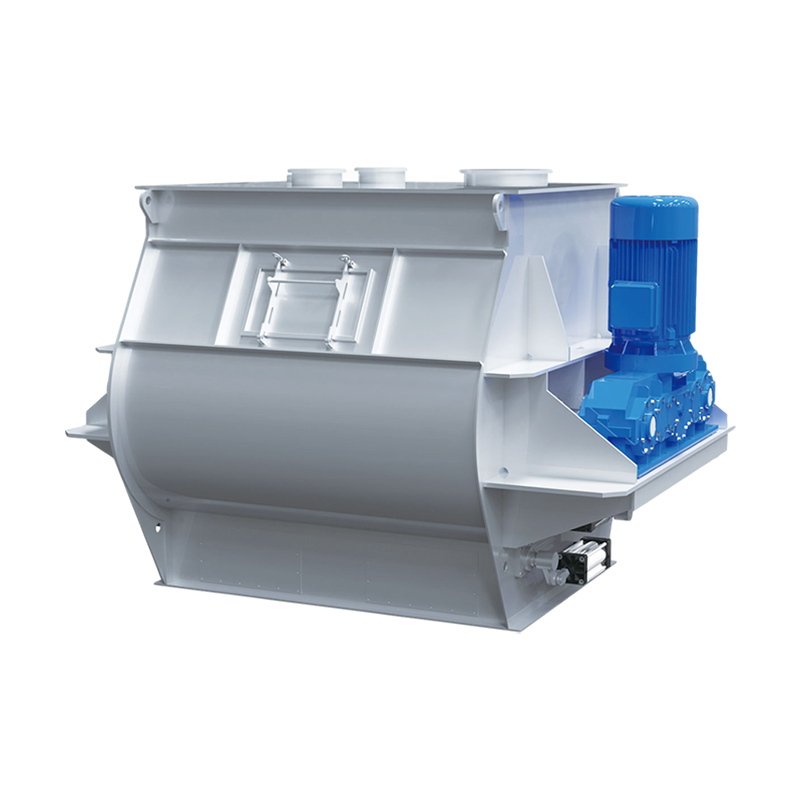

Ribbon Blender Plough-shear Mixer

Plough-shear Mixer Ob Chav Ncej Paddle Tov Khoom

Ob Chav Ncej Paddle Tov Khoom CM Series tov khoom

CM Series tov khoom